Hydrocarbon resin is a thermoplastic resin produced by pretreatment, polymerization, distillation, and other processes of C5 and C9 fractions produced by petroleum cracking. It is not a high polymer, but an oligomer with a molecular weight of 300-3000.

Origin

Petroleum resin is named after the source of petroleum derivatives. It has the characteristics of low acid value, good miscibility, water resistance, ethanol resistance, and chemical resistance. It is chemically stable to acid and alkali and has good viscosity adjustment and thermal stability. Petroleum resins are generally not used alone but are used together as accelerators, regulators, modifiers, and other resins.

Classification

Petroleum resins can be generally classified into four types: C5 aliphatic, C9 aromatic, DCPD, and pure monomers such as poly SM, AMS, etc. The constituent molecules are all hydrocarbons, so they are also called hydrocarbon resins.

Petroleum resins are classified into aliphatic resins (C5), cycloaliphatic resins (DCPD), aromatic resins (C9), aliphatic/aromatic copolymer resins (C5/C9), and hydrogenated petroleum resins according to different raw materials. C5 hydrogenated petroleum resin, C9 hydrogenated petroleum resin.

C5 petroleum resin, also known as C5 resin and aliphatic hydrocarbon resin, is divided into three types: general-purpose type, harmonious type, and primary color transparent type.

Advantage

Petroleum resin is a newly developed chemical product in recent years. Because of its advantages of low price, good miscibility, low melting point, water resistance, ethanol resistance and chemical resistance, it can be widely used in rubber, adhesives, coatings, paper, ink, etc. Various industries and fields.

Structure

Chemical element structure model of petroleum resin:

The most widely used petroleum resin production applications are C9 petroleum resin and C5 petroleum resin.

C9 Petroleum Resin

C9 petroleum resin specifically refers to a resinous substance obtained by “polymerizing olefins or cyclic olefins or copolymerizing with aldehydes, aromatic hydrocarbons, terpene compounds, etc.” containing nine carbon atoms.

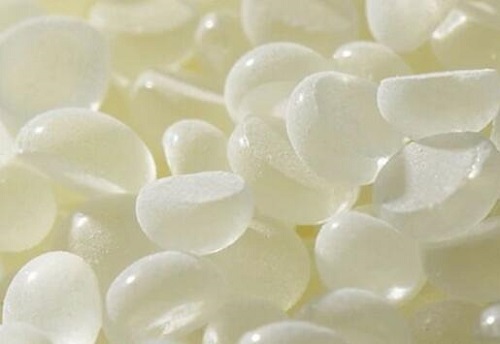

C9 petroleum resin, also known as aromatic petroleum resin, is divided into thermal polymerization, cold polymerization, tar and other types. Among them, the products of cold polymerization are light in color, good in quality, and have an average molecular weight of 2000-5000. Light yellow to light brown flake, granular or massive solid, transparent and shiny, relative density 0.97~1.04. The softening point is 80~140℃. The glass transition temperature is 81°C. Refractive index 1.512. Flashpoint 260 ℃. Acid value 0.1~1.0. The iodine value is 30~120. Soluble in acetone, methyl ethyl ketone, cyclohexane, dichloromethane, ethyl acetate, toluene, gasoline, etc. Insoluble in ethanol and water. It has a cyclic structure, contains some double bonds, and has strong cohesion. There are no polar or functional groups in the molecular structure and no chemical activity. Good acid and alkali resistance, chemical resistance and water resistance. Poor adhesion, brittleness, and poor aging resistance, should not be used alone. It has good compatibility with phenolic resin, coumarone resin, terpene resin, SBR and SIS, but has poor compatibility with non-polar polymers due to its high polarity. Combustible. Nontoxic.

C5 Petroleum Resin

C5 petroleum resin, also known as C5 resin and aliphatic hydrocarbon resin, is divided into three types: general-purpose type, harmonious type, and primary color transparent type. The average molecular weight is 1000~2500. Light yellow or light brown flake or granular solid. Relative density 0.97-1.07. The softening point is 70~140℃. Refractive index 1.512. Soluble in acetone, methyl ethyl ketone, ethyl acetate, trichloroethane, cyclohexane, toluene, solvent gasoline, etc. It has good viscosity, heat resistance, stability, water resistance, acid and alkali resistance, and the viscosity enhancement effect is better than C9 petroleum resin. It has good compatibility with phenolic resin, terpene resin, coumarone resin, natural rubber, synthetic rubber, etc., especially with styrene-butadiene rubber (SBR). Combustible. Nontoxic.

C5 petroleum resin began to replace natural resin adhesives (rosin and terpene resins) with its characteristics of high peel bonding strength, good adhesion, stable adhesion performance, moderate melt viscosity, good heat resistance, good compatibility with polymer matrix, and low price.

The characteristics of refined C5 petroleum resin in hot melt adhesives: good fluidity, can improve the wettability of the main material, good viscosity, and outstanding initial tack performance. Excellent anti-aging properties, light color, transparency, low odor, low volatiles. In hot melt adhesives, the ZC-1288D series can be used alone as tackifying resin or mixed with other tackifying resins to improve certain characteristics of hot melt adhesives.

Application

Hot melt adhesive

Other applications: hot melt pressure-sensitive adhesive, solvent pressure-sensitive adhesive.

The performance and function of petroleum resin in different industries:

1. Paint

The paint mainly uses C9 petroleum resin, DCPD resin and C5/C9 copolymer resin with a high softening point. Adding petroleum resin to the paint can increase the gloss of the paint, improve the adhesion, hardness, acid resistance and alkali resistance of the paint film.

2. Rubber

Rubber mainly uses low softening point C5 petroleum resin, C5/C9 copolymer resin and DCPD resin. This kind of resin has good mutual solubility with natural rubber particles and has no great influence on the rubber vulcanization process. Adding petroleum resin to the rubber can play the role of tackifying, reinforcing and softening. In particular, the addition of C5/C9 copolymer resin can not only increase the adhesion between rubber particles but also improve the adhesion between rubber particles and cords. It is suitable for rubber products with high requirements such as radial tires.

3. Adhesive industry

Petroleum resins have good adhesive properties. Adding petroleum resins to adhesives and pressure-sensitive tapes can improve the adhesive force, acid resistance, alkali resistance and water resistance of the adhesives, and can effectively reduce production costs.

4. Ink industry

Petroleum resins for inks are mainly high softening point C9 petroleum resins and DCPD resins. The addition of petroleum resin to the ink can play the role of color development, quick-drying, brightening, and improving printing performance.

5. Coating industry

Coatings for road signs and road markings, petroleum resin has good adhesion to concrete or asphalt pavement, and has good wear resistance and water resistance, and has good affinity with inorganic substances, easy to coat, good weather resistance, Fast drying, high firmness, and can improve the physical and chemical properties of the layer, improve UV resistance and weather resistance. Petroleum resin road marking paint is gradually becoming mainstream, and the demand is increasing year by year.

6. Other

Resin has a certain degree of unsaturation and can be used as a paper sizing agent, plastic modifier, etc.

Petroleum resin is a non-dangerous product and should be protected from sunlight and rain during transportation. Not to be transported together with pyrophoric substances, strong oxidants, and strong acids.

Petroleum resin should be stored in a ventilated, cool and dry environment. The storage period is generally one year, and it can still be used after one year if it passes the inspection.